Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the evolving landscape of energy management, understanding Thyristor Controllers is crucial. Renowned expert Dr. Alan Smith once stated, "Thyristor Controllers are essential for enhancing power efficiency." This highlights their role in modern systems.

Thyristor Controllers can significantly improve energy usage in various applications. They play key roles in controlling voltage and current flow. Efficient management helps reduce costs and environmental impact. However, implementing them is not without challenges.

Many face difficulties with integration and calibration. Operators must consider specific needs carefully. It’s vital to learn from past implementations. Adjustments might be necessary to achieve optimal performance. Embracing Thyristor Controllers can lead to smarter energy solutions. Yet, ongoing analysis is essential for continuous improvement.

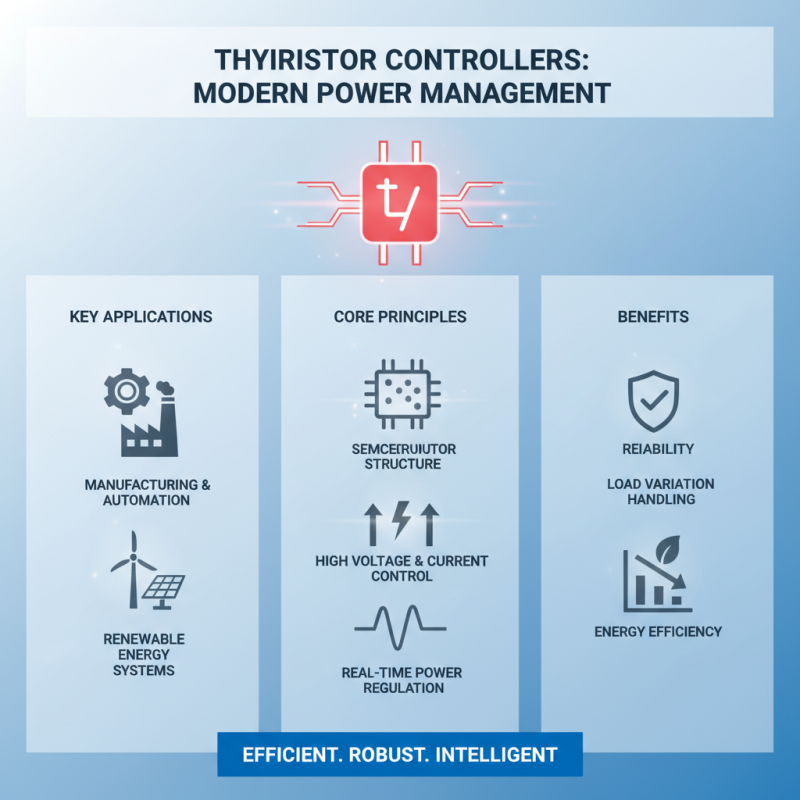

Thyristor controllers play a crucial role in modern power management. These devices efficiently regulate electrical power in various applications, from industrial equipment to renewable energy systems. With a semiconductor structure, thyristors can control high voltages and currents, making them ideal for adjusting power levels in real time. They are reliable and can handle significant load variations.

In practical applications, thyristor controllers can be found in motor drives and lighting systems. Their ability to control phase angles allows for finer energy management. For instance, in a motor control setup, using a thyristor can lead to smoother operations and less energy waste. However, implementing them effectively can be challenging. Users often struggle with overheating issues or noise generation, which can complicate designs.

While thyristor technology is advancing, it is not without its flaws. The initial setup can be complex, sometimes requiring substantial adjustments. Maintenance can be an ongoing concern, as components may degrade over time. As more industries adopt this technology, continuous refinement of control strategies will be necessary to ensure optimal performance.

Thyristors are semiconductor devices essential for controlling electrical power. They act as switches, allowing and stopping current flow. Their structure includes four layers of alternating P and N-type materials. This design gives them unique capabilities, making them suitable for high-power applications.

In practical use, thyristors enable efficient power management in various systems. They can handle high voltages and currents, which is crucial for industrial use. However, their control mechanism can be challenging. Users must carefully manage firing angles to maintain desired performance. Incorrect management can lead to heat generation or system instability.

Understanding how thyristors function is vital for effective application. They turn on when a forward voltage is applied and remain on until the current drops. This means that precise timing in triggering is key. Often, people overlook this, resulting in inefficiencies. Experimentation and reflection are necessary to master thyristor control for optimal outcomes.

Thyristor controllers are vital in modern power systems. They regulate power flow efficiently, reducing energy losses. According to a 2022 industry report, using these controllers can improve energy efficiency by up to 30%. This is significant for both industrial and residential applications.

In renewable energy systems, thyristor controllers play a key role. They manage power from solar and wind sources effectively. For instance, they facilitate maximum power point tracking in photovoltaic systems. These controllers adapt quickly to changing conditions, helping to stabilize the grid. However, integration can be complex, and designers often face challenges in compatibility with existing infrastructure.

In industrial settings, thyristor controllers enhance motor control. They provide precise speed regulation, which is crucial for manufacturing processes. A well-known fact is that energy consumption in the industrial sector accounts for nearly 30% of total electricity use. Yet, many facilities still underutilize these technologies. Continual advancements in thyristor technology promise better performance but require constant learning and adaptation from engineers.

Thyristor controllers are gaining traction in energy-efficient power management. They effectively regulate power flow in various applications. This technology can enhance energy efficiency significantly, leading to cost savings. A recent report indicates that using thyristor controllers can reduce energy consumption by up to 30%. This statistic highlights their potential impact on both industrial and residential sectors.

Implementing these controllers can be challenging. For instance, proper system design is crucial to avoid inefficiencies. Misconfigurations may lead to increased emissions and energy wastage. Additionally, regular maintenance is essential. Neglecting this aspect might diminish the controllers' efficiency over time. Research shows that maintenance can improve performance by nearly 15%, underscoring its importance.

The adaptability of thyristor controllers is notable. They work well in different environments and applications. Their capacity to manage varying loads optimizes energy use. However, without understanding the specific needs of the system, benefits may not be fully realized. Poor integration could negate any potential advantages. Careful consideration and planning are essential for maximizing the efficiency of thyristor controllers.

| Parameter | Description | Efficiency Gain (%) | Typical Applications |

|---|---|---|---|

| Voltage Control | Modulation of voltage levels for improved performance | 15% | Electric motors, heating systems |

| Harmonic Reduction | Minimizing harmonics for enhanced power quality | 20% | Industrial automation, power systems |

| Temperature Control | Precise temperature adjustments for energy savings | 18% | HVAC systems, temperature-sensitive processes |

| Load Management | Balancing load to optimize power consumption | 25% | Data centers, manufacturing plants |

| Switching Speed | Rapid switching for dynamic energy control | 10% | Renewable energy systems, UPS systems |

In industrial settings, implementing thyristor controllers can significantly enhance power management. These devices offer precise control over electrical power by regulating voltage and current. When integrating thyristor controllers, understanding their application is key. A thorough assessment of your energy needs should precede installation. This ensures that the chosen configuration is suitable for your specific environment.

Tips: Consider the load types in your facility. Resistive loads might behave differently than inductive ones. Ensure the thyristor controllers can handle these variations effectively. Also, monitor the thermal performance of the controllers. Overheating can lead to inefficiencies or even failures.

Testing and regular maintenance are crucial. Set up a routine to check connections and functionality. An overlooked component can result in unplanned downtime. Evaluate your control strategy continuously. What worked last year may not be effective now. Stay flexible. Adaptation is a part of efficient power management.